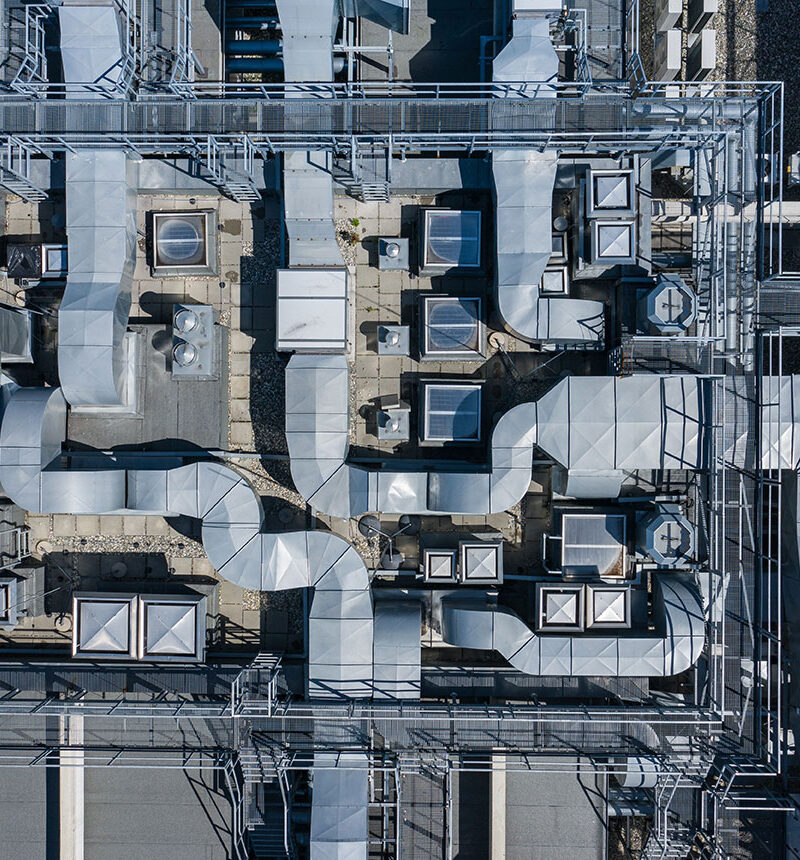

HVAC

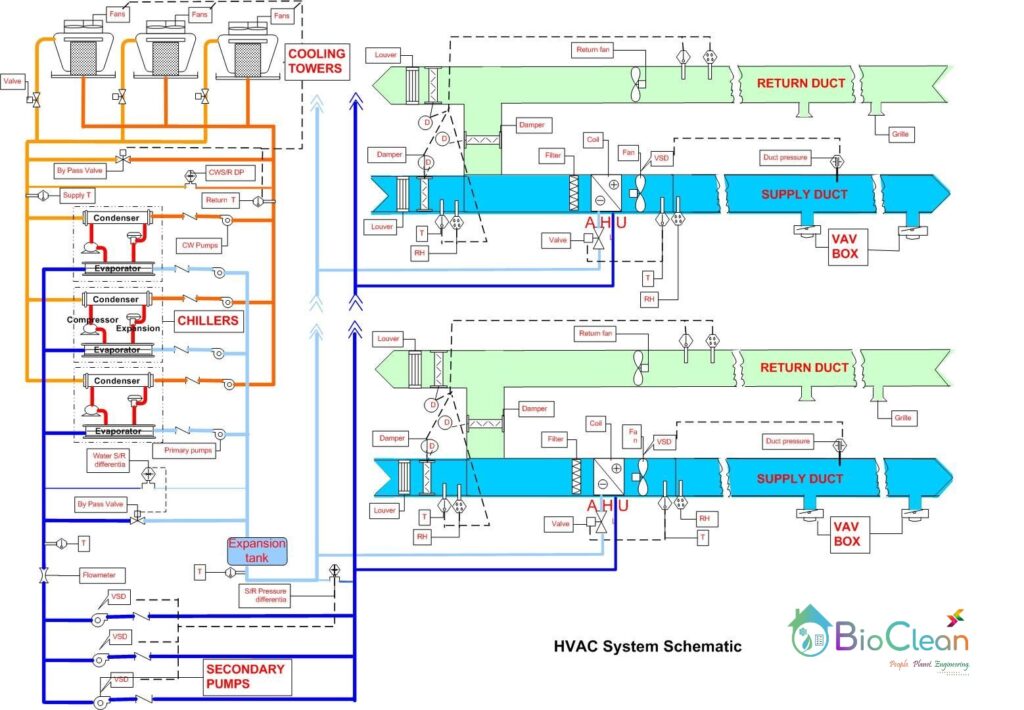

HVAC usually refers to the mechanical system of the building that provides heating, ventilation and/or cooling within a building or a premise. This includes Air conditioners, Motor- blower assembly, Evaporative coil, Compressor, Compressor coil, Thermostats, Ductwork, Modules, Filters, Grilles, Diffusers and Dampers which help to distribute the conditioned air within a building. We follow very stringent quality control systems and up to date guidelines, where we ensure every raw material received and every manufactured item is tested and approved as per the set quality norms. This ensures optimum performance of the equipments.

Regulators requires manufacturing companies to conform to cGMP (current Good Manufacturing Practices). These regulations, which have the force of law, require that manufacturers, processors, and packagers of drugs to take proactive steps to ensure that their products are safe. HVAC system plays a major role in this. More than half of Input Energy among Utilities and Equipment, HVAC Consumes, so its a very crucial part of Design & Selection and has to be optimum designed.

Our HVAC Turnkey Solutions Involves

Building Survey & Feasibility Study

Feasibility studies are preliminary studies undertaken in the very early stage of a project. The purpose of Feasibility study is to collect the required input details from the client to do our load calculations.

Concept Design Submittal (Design Basis Report)

We will prepare and submit a report of findings with options considered, evaluation criteria, and recommendations. And we will submit Design basis report will contain all load calculation report, System selections, Advantage of proposed system, Energy saving though innovative design, implementation of new technologies, Energy analysis & cost analysis.

Budgetary Proposal

Approximate budget estimation of Proposed project which helps Client to make their project budget.

Heating and Cooling Load Calculations

Performing heating and cooling load calculations for all conditioned building spaces to determine the zones and capacity of the new heating, ventilation, and air conditioning. Calculations will be based on: conduction and convection heat transmission, air ventilation and infiltration, solar heat gain, maximum anticipated staff and public occupancy, existing and future equipment, machines, appliances, and other internal building heat sources. Identify and locate all of the equipment, machines, appliances, and other similar internal building heat sources on the floor plans of the building. Include their BTU ratings so they can be used for the heating and cooling load calculations and future air conditioning system balancing.

HVAC Systems selections

The HVAC Design will comply with all applicable codes and provide a design for the air conditioning, ventilation, and controls, considering efficiencies, life cycle operating and maintenance costs, energy rebates and/or grants, costs and schedules, etc. Includes all equipment’s schedules on the drawings indicating the air conditioning equipment’s by symbol designation, name and estimated size or capacity in TR/BTU, GPM, gallons, etc. Include ventilation schedules for all building spaces. Indicate the location of all air conditioning equipment, all major piping, and all duct runs in the mechanical room and floors of the building.

Duct Layout/Plant Layout

The layout will be designed in such a way for maximum air distribution. We will provide a design which includes plenums, ductwork, blowers, registers, grills, diffusers, dampers, volume adjustment devices, controls, etc. And will provide for proper outside air ventilation and air change quantities for the building.

Preparation of Bill of Quantities

Final bill of quantity will contain list of item in project and its quantity as per the final design drawings.

Preparation of Material Specification

Material specification will contain required detail of a material / equipment by the design, construction and performance of all listed item in BOQ.

Preparation of Tender Document

Tender document is final document issued to the specified contractor which contains all below three documents Tender Drawings Tender Bill of quantity Tender specification (will contain scope of work, approved makes and material specification)

Approval of all Data Sheets & Technical submittal

Verification of contractor construction document (like equipment technical data sheet, GA drawings, equipment performance curve) and construction drawings and approving the same.

Construction and Commissioning Management

Verification of project schedule, Inspection of supplied equipment’s, inspection of work quality and final verification of equipment commissioning report and approving the same.

Construction and Commissioning

Execution of Project and Handing Over the site as per Schedule to the client with proper validation and reports.

Documentations

Documentation like DQ, IQ, OQ and Test Reports (PQ) as per ISO guidelines.

Air Handling Units & DHUs

Bio Clean Deals with Approved & World Class Makes of AHUs, Best in Class – Eurovent Designed, EN 1886 – EN 13053 TUV Certified AHUs. An Air Handler (AHU), is a device used to condition and circulate air as part of a Heating, Ventilating and Air-Conditioning System. AHUs are connected with duct- work to cater the area to be conditioned for Low Relative Humidity required area. Dehumidifier Units are used, whose Desiccant wheel with help of heaters reduces excess humidity from Air. Dehumidifiers are available in size from 100 CMH to 50,000 CMH

Range Of Air Handling Units

- Floor Mounted Air Handling Units

- Double Skin

- Single Skin

- Re-Circulation

- Ventilation

- DeHumidifiers

- Heat Recovery Ventilator (HRV)

A Working Model example of AHU with Heat Recovery System

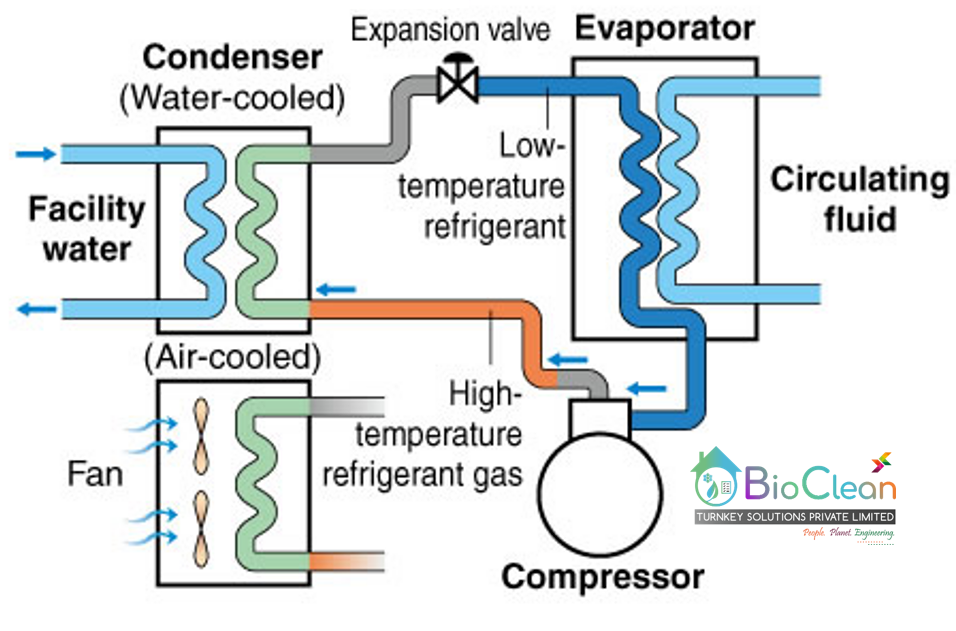

DX Systems & Chiller

(Heart of HVAC)

1. Fixed Speed / Inverter Type DX System

2. Chillers

Water-Cooled Chillers

Air-Cooled Chillers

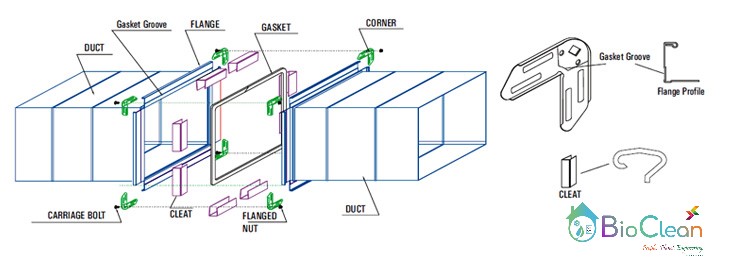

Ducts

1. Site Fabricated Ducts

2. Pre Fabricated Ducts

3. TDF Ducts

4. Pre-Insulated Ducts

Air Diffusing Ports

Grills, Diffusers, jet nozzles with dampers to diffuse the required amount of conditioned air into the room and thereby produce a controlled environment.

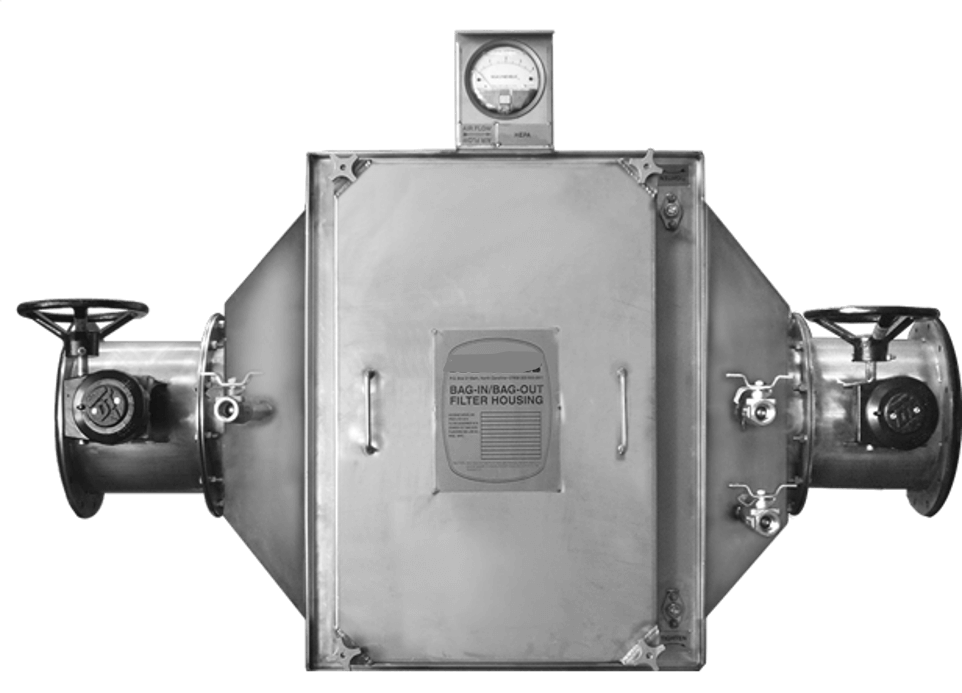

GEL-SEAL HEPA

BAG-IN – BAG-OUT FILTERS

ULFA FILTERS WITH MODULES

HEPA | ULFA Filters

Final stage filtration, usually mounted in the room and sometimes within the AHU, capable of filtering air upto 99.997% and of particles whose diameter is equal to 0.3 microns thereby making it a mandatory product for classified areas.

Related Services

TURNKEY CLEANROOM SOLUTIONS

WALKABLE CEILING PANELS

FIRE RATED DOORS

METAL DOORS

ELECTRICALS & CONTROLS

HVAC CONTROLLERS AND SENSORS

BUILDING MANAGEMENT SYSTEM

DOOR INTERLOCKING SYSTEM

DDC - HMI & PLC - SCADA

ENGINEERING CONSULTANCY

FROM IDEA TO CONCEPTUALIZATION

PROJECT MGMT. AND CONTROL

INST, COMM & VALIDATIONs

PHARMA UTILITIES & DISTRIBUTION

COMPRESSED AIR

STEAM ETC

PHARMA PROCESS EQUIPMENT

TRACK AND TRACE SYSTEM

PACKING EQUIPMENT

FIRE FIGHTING SYSTEM

GAS SUPPRESSION SYSTEM

FIRE ALARM SYSTEM

FIRE EXTINGUISHER