Cleanroom Equipments

(DISPENSING / SAMPLING BOOTHS)

Sampling & Dispensing Booth are overhead air modules that work on the principle of laminar airflow with HEPA filters and pre-filters. It is used for preventing powder contamination while filling, weighing and sampling/ dispensing of raw material. It utilizes downward draught air flow technique to prevent airborne dust from harming the operator or contaminating the surrounding environment.

Specification & Features:

- MOC: SS304 / SS316 or customized execution

- Side panel: Rigid SS 304 double wall

- Pre-filter: Eu-4

- Intermediate air filter: Eu-7

- Final Filter: H-14

- Exhaust HEPA: H-14

- PAO port

- Mechanical differential gauge across pre, intermediate and final filter

- Ventilator

- LED Light

- Electrical control system with push button and indicators

- Switch socket

- Service access: Front or back

- Dedicated control panel

- Drag shield

- Air cleanliness level: ISO 5

- Air Flow: Vertical re-circulatory

- Air flow visualization

- Noise Level: Less than 70db A when ambient is not more than 55db A

- Light Intensity: 250-300 lux Air Velocity: 0.45mps (± 0.05mps)

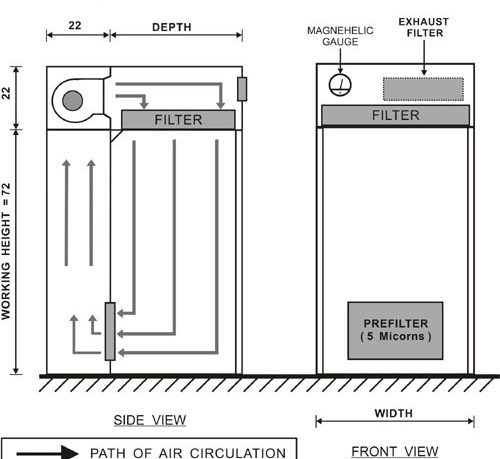

VERTICAL LAF

A laminar flow cabinet is an enclosed box designed to prevent contamination of Chemicals, Pharmecutical samples, or any particle sensitive materials. In a laminar flow Air is drawn through a HEPA filter and blown in a very smooth way. The cabinet is made in such a way using high grade of stainless steel and constructed with CNC and NC machines for smooth edges and no gaps ensures collection of particles. VLAF offers proven protection for samples and processes. The work station is continuously supplied with positive pressure HEPA filtered vertical air flow. The vertical unidirectional airflow speed prevents contamination from operator and environment to work station. The laminarity of the flow prevents cross-contamination between the items handled in the working space.

GENERAL SPECIFICATIONS

- Glass side panels

- Two stage filtration

- o EU6 – Prefilters (95% down to 5 micron)

- o EU14 – HEPA filter (99.999% down to 0.3micron) at supply position

- Statistically and dynamically balanced motor blower with suspension arrangement to reduce noise level.

- SS work table with due reinforcementFluorescent lights with milky white diffuser

- Fluorescent lights with milky white diffuser

- Differential pressure gauge : 1no

- On / off switches

- Clean down timer with operation hold indicator

- DOP test port

- 5/15 Amp switch socket for external equipment.

OPERATING CONDITIONS

- Air cleanliness : ISO class 5 (ISO 14644-1:1999(E))

- Air velocities : 0.45 +/_ 0.05mps

- Air flow : Horizontal

- Noise level : less than 67db

- Vibration level : minimum

- Light intensity : >300Lux

- Power supply : 230V AC 1-0 50HZ

OPTIONS AND ACCESSORIES

- A wide range of configurations to suit any containment application:

- Front doors (Hinged / Pneumatic cylinder

- U.V.Light with hour meter

- S.S.304 Air /Gas cock

- Night mode operation

- Filter blocked alarms (Audible and visible)

- Velocity display with alarms (Audible and visible)

- Explosion proof electrics for flame proof applications.

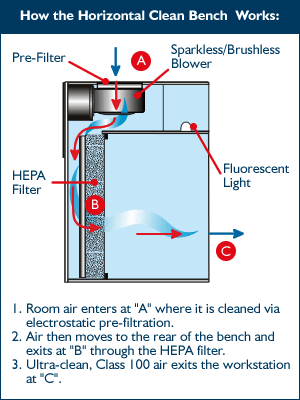

HORIZONTAL LAF

HLAF is designed for offering highest product protection by providing ISO class 5 particle free work station for handling critical process. HLAF offers proven protection for samples and processes.

The work station is continuously supplied with positive pressure HEPA filtered horizontal air flow. The horizontal unidirectional airflow speed prevents contamination from operator and environment to work station such as injectable medicines, cell and tissue cultures, food sample preparation for sterility testing, sterile packaging and I.V. pharmacy preparations as well as micromechanics, optics, electronics. BCIAS-HLAF is available in powder coated G.I steel, S.S.316, S.S.316 L or a combination of both.

- MOC: SS304, SS316 and SS316L or customized execution

- Stand and worktable: SS304, SS316 and SS316L or customized execution

- Back panel: SS304, SS316 and SS316L or customized execution

- Side panel: Flushed glass

- Pre-filter: EU-7

- Final Filter: H-14

- PAO port

- Mechanical differential gauge across final filter

- Ventilator

- LED Light

- Electrical control system with push button and indicators

- Air flow visualization

- Air Cleanliness Level ISO – 5

- Noise Level: Less than 70db A when ambient is not more than 55db A

- Air Velocity: 0.45mps (± 0.05mps)

- Air Flow: Vertical

- Light Intensity: 250-300 lux

- Air flow visualization

Pass Box

In pharmaceuticals manufacturing facilities, it is essential to minimise man / material movement and avoid cross contamination between different classified areas to achieve desired classification and to maintain integrity of products and processes. Pass Box is designed to allow material transfer without much personnel movement. It also aids controlling ingress of particulate contaminants into clean room and between different classified areas.

In pharmaceuticals manufacturing facilities, it is essential to minimise man / material movement and avoid cross contamination between different classified areas to achieve desired classification and to maintain integrity of products and processes. Pass Box is designed to allow material transfer without much personnel movement. It also aids controlling ingress of particulate contaminants into clean room and between different classified areas.

STATIC PASSBOX

A static pass box is designed to transfer material between clean environments which are equally clean and designed to work with minimal personal movement. A static pass box cannot be used to transfer material between a clean area and a non-clean area.

- Material: SS 304

- Surface Finish: Matt

- Internal Size: 750mm (L) X 450mm (W) X 900mm (H)

- One stage filtration

- Double walled flush glass view panels provided with doors, Handle and hinges

- U.V. Light

- Floor mounted construction with three side wall structure

- Support Stand for Mounting the Pass Box

- Flange for filling the gap between the pass box and the clean room wall

DYNAMIC PASSBOX

A dynamic pass box is a box which is designed to transfer material from an unclassified area to a controlled area and has got interlocked doors located on both sides with necessary filter and technical arrangements which prevents contamination transfer in controlled environment.

- Two stage filtration, EU6-Prefilter (95% down to 5 micron), EU14-HEPA Filter (99.999% / AZ 0.3 Micron)

- Dynamically balanced motor – blower facilitated with suspension arrangement to minimize the WC noise level

- Double walled flush glass view panels provided with doors, SS Handles and SS hinges

- Internal Covings for easy cleaning, Door interlocking with Electro-magnetic Interlocking

- Differential Pressure Gauge: 1 No. On/Off Switch for Motor & DOP Test Port

- U.V. Light with Hour Meter with interlocking arrangement to put-off U.V. Light if any of the door opens

- Floor mounted construction with three side wall structure & Door Drop Seal

- Support Stand for Mounting the Pass Box

- Flange for filling the gap between the pass box and the clean room wall

- Audio / Visual alarm for blower tripping with Fault Acknowledgement & Reset Switch

- Clean Down Timer with Operation Hold Indicator & interlocking to put on fluorescent lights only after clean down time over

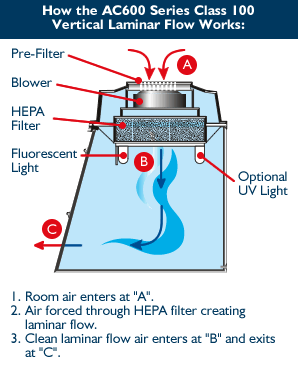

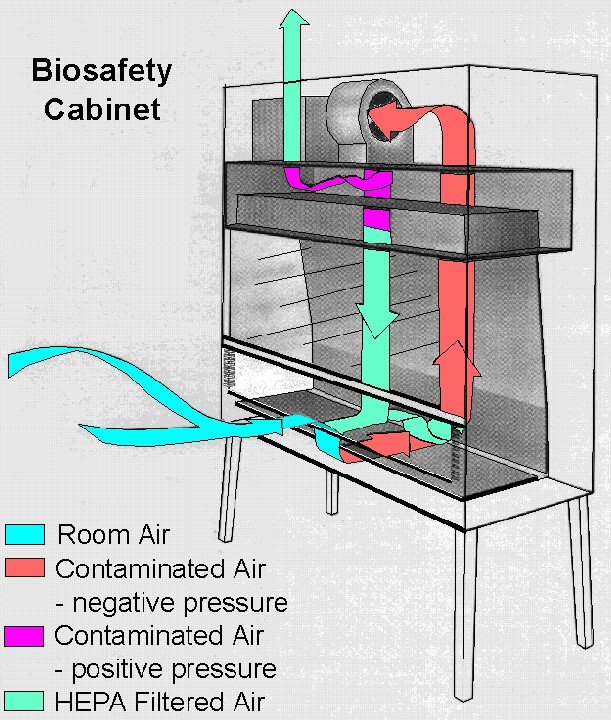

BIO SAFETY CABINET

Bio-safety cabinets are designed to provide personnel, environmental and product protection. Air flow is drawn around the operator into the front grille of the cabinet which provides personnel protection. Additionally, the downward laminar flow of HEPA-filtered air provides product protection by minimizing the chance of cross-contamination along the work surface of the cabinet. Because cabinet air passes through the exhaust HEPA filter, it is contaminant-free (environmental protection). All Class II cabinets are designed for work involving microorganisms assigned to bio safety levels 1, 2 and 3. Class II cabinets provide the microbe-free work environment necessary for cell culture propagation, and also may be used for the formulation of non-volatile antineoplastic or hemotherapeutic drugs. Bio safety cabinets are available in powder coated Galvanized Steel, SS 304 / SS 316 or a combination of both.

- Filters series- Fine (5 µ) and HEPA (0.3)

- Pre Filter – Make: AAF

- Hepa Filter, Make: AAF or Equivalent, Efficiency- 99.997 down to 0.3µ

- Gaskit – Self Adhesive Neoprene Gasket

- Sealant – Epoxy Based, Non Soluble

- Coving – SS coving

- Air velocity – 90 ±20 FPM

- Class -100

- Blower type – AC Centrifugal Type (Dual In late), Impeller (Aluminum/GI)

- MOC Housing -(GI)

- Make of Motor -GE /EBM-Crompton /equivalent

- Air flow type- Vertical

- Light Fixtures- Philips/Anchor/Roma or equivalent

- Gas Cock – Standard

- Electrical Sockets- Philips/Anchor/Roma or equivalent, 230V, 50 Hz,Single Phase

- Magnehelic Gauge

- Diff. pressure across filter (Range)- 0-50MM WC

- Grills -SS mat finish protective grill for HEPA & Pre filter

- DOP Port -Std

- Noise level-65±5 db

- Door at front side- U.V. Protected Acrylic Door with Movable Vertical Automatic

- Magnehelic Gauge

- Diff. pressure across filter (Range)- 0-50MM WC

- Grills -SS mat finish protective grill for HEPA & Pre filter

- DOP Port – Std

- UV Light: Philips

- Hour Meter: inbuilt in controller

AIR SHOWER

Air showers are specialized enclosed antechambers which are incorporated as entry-

ways or cleanrooms and other controlled environments to reduce particle contami-

nation. Air showers utilize high-pressure, HEPA- or ULPA-filtered air to remove dust,

fibrous lint and other contaminants from personnel or object surfaces. The forceful

“cleansing” of surfaces prior to entering clean environments reduces the number of

airborne particulates introduced

- MOC: Gl powder coated, SS304, SS316 and SS316L or customized execution

- Front door: Doubled wall SS doors with flush glass view panel, hinges & handles

- SS perforated floor

- Door closure

- Air Nozzle

- Electromagnetic doors interlock

- Air pre-filter: EU-7

- Final Filter: H-14

- LED Light

- Air Flow: Turbulent

- Mechanical differential gauge across filter

- Emergency switch inside air shower

- Ventilator

- Air Velocity: 4000 - 5000 fpm

- Light Intensity: 250 - 300 lux

- Air Flow: Turbulent

DE DUSTING BOOTH

A de dusting booth is a system used to enhance the quality of air released from in dustrial and commercial processes by collecting dust and other impurities from air orgas. Designed to handle high-volume dust loads, a dust collector system consists of ablower, dust filter, a filter-cleaning system, and a dust receptacle or dust removal sys-tem. It is distinguished from air purifiers, which use disposable filters to remove dust.

Related Services

TURNKEY CLEANROOM SOLUTIONS

WALKABLE CEILING PANELS

FIRE RATED DOORS

METAL DOORS

ELECTRICALS & CONTROLS

HVAC CONTROLLERS AND SENSORS

BUILDING MANAGEMENT SYSTEM

DOOR INTERLOCKING SYSTEM

DDC - HMI & PLC - SCADA

ENGINEERING CONSULTANCY

FROM IDEA TO CONCEPTUALIZATION

PROJECT MGMT. AND CONTROL

INST, COMM & VALIDATIONs

TURNKEY HVAC SOLUTIONS

PRE FABRICATED DUCTS

AIR HANDLING UNITS

DEHUMIDIFIERS

PHARMA PROCESS EQUIPMENT

TRACK AND TRACE SYSTEM

PACKING EQUIPMENT

FIRE FIGHTING SYSTEM

GAS SUPPRESSION SYSTEM

FIRE ALARM SYSTEM

FIRE EXTINGUISHER